Hard Board

Description

HARDBOARD is made from wood fiber, which is extracted from chips and pulp. In the production process the pulp is exploded under pressure. Heat and steam is applied, leaving a fine, fluffy brown fiber. These fibers are transformed into mats, which are held togerther with lignin, naturally occurred from hardwood. The matt are then pressed between steam-heated metal plates to give grain less sheets with one smooth gloss surface and one textured surface. To reduce warping or improvemoisture resistance, moisture is added abck in using a humidification process, where appropriate moisture content is a dded back the board.

Features

- Hardboard has many of the desirable esthetics character of wood, without the grain structure and knots found in natural wood products. Hardboard is an EO product, no eyes/skin irritation for its wide range of application..

- Hardboard gives supeior flexural strength and stiffness over a wide range of temperatures..

- Hardboard shows better dimensional stability than many plastic materials in typical vehicle compartment conditions..

- Hardboard provides a superb surface for painting, boanding, laminating and coating applications, and dielectric and vacuum-covering operations..

- Used in a sandwich construction with a low-density core, hardboard provides a strong, lightweight option for lead bearing applications. Hardboard is a good choice for passenger area sound blocking applications. Combined with a sound absorption material, hardboard creates a first-rate acoustic package..

|

Environment Freindly. 100% Wood Fiber |

|

Asbestos Free |

|

Ease of Workability |

|

Cost Saving |

|

100% Formaldehyde Free : E0 Product (Tested by SGS JIS A 1460:2001) |

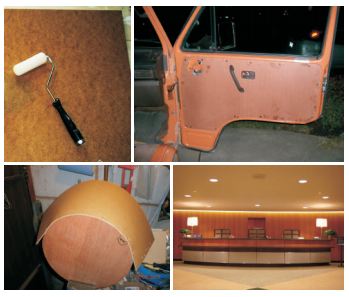

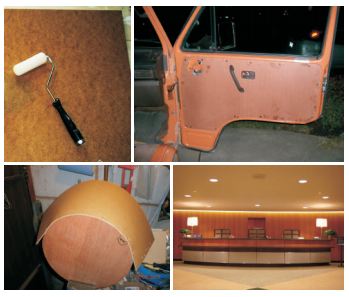

Applications

The important benefits of high structural strength, good dimensional stability, durability, smooth & glossy surface enable the hardboard ideal use in furniture, door manufacturing, packaging, automative industry.

Example

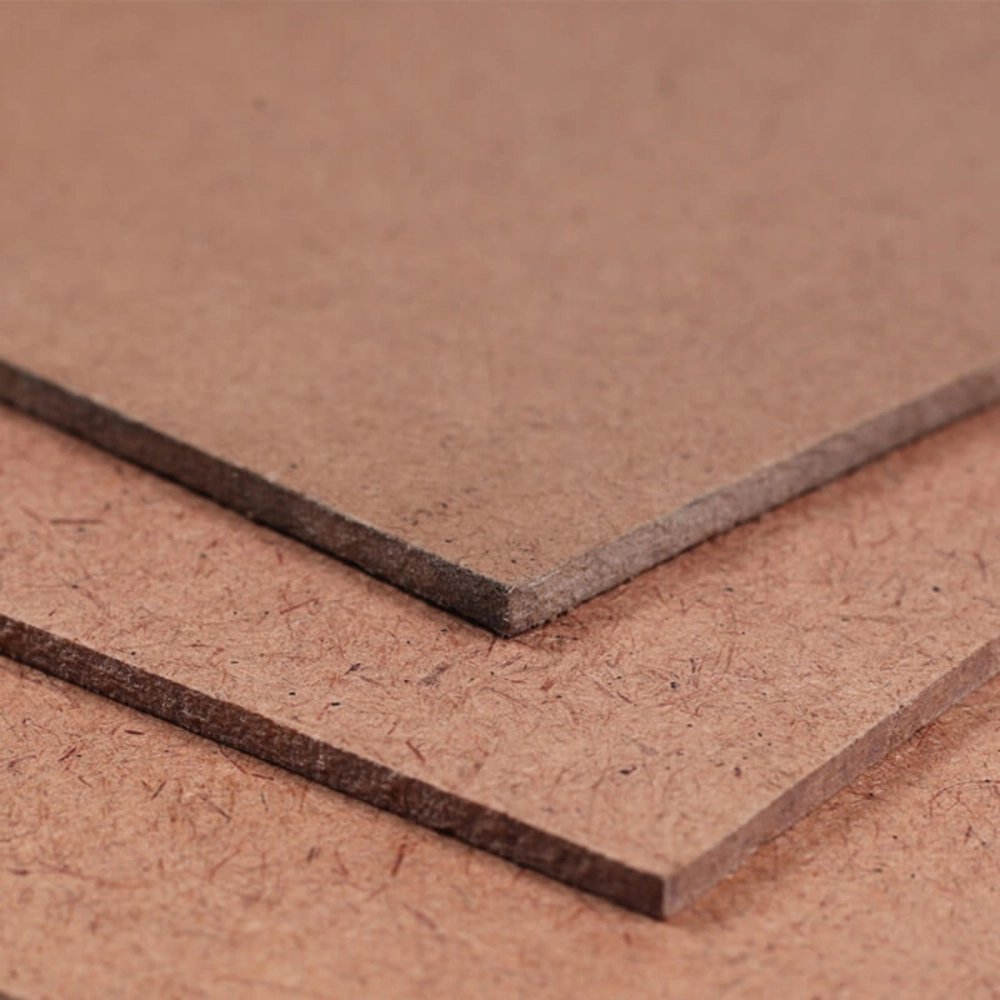

Hardboard Surface

|

|

| Top: Smooth Gloss Surface | Bottom: Textured Surface |

Storage & Handling

|

Store under shade, dry and leveling area on timber bases. |

|

Handle vertically from both edges with two or more persons to prevent sagging of the board |

Disclaimer

All product images shown are for illustration purposes only. Actual products may varies in term of size, type, brand, version, colour, and other relevant characteristics.

Description

HARDBOARD is made from wood fiber, which is extracted from chips and pulp. In the production process the pulp is exploded under pressure. Heat and steam is applied, leaving a fine, fluffy brown fiber. These fibers are transformed into mats, which are held togerther with lignin, naturally occurred from hardwood. The matt are then pressed between steam-heated metal plates to give grain less sheets with one smooth gloss surface and one textured surface. To reduce warping or improvemoisture resistance, moisture is added abck in using a humidification process, where appropriate moisture content is a dded back the board.

Features

- Hardboard has many of the desirable esthetics character of wood, without the grain structure and knots found in natural wood products. Hardboard is an EO product, no eyes/skin irritation for its wide range of application..

- Hardboard gives supeior flexural strength and stiffness over a wide range of temperatures..

- Hardboard shows better dimensional stability than many plastic materials in typical vehicle compartment conditions..

- Hardboard provides a superb surface for painting, boanding, laminating and coating applications, and dielectric and vacuum-covering operations..

- Used in a sandwich construction with a low-density core, hardboard provides a strong, lightweight option for lead bearing applications. Hardboard is a good choice for passenger area sound blocking applications. Combined with a sound absorption material, hardboard creates a first-rate acoustic package..

|

Environment Freindly. 100% Wood Fiber |

|

Asbestos Free |

|

Ease of Workability |

|

Cost Saving |

|

100% Formaldehyde Free : E0 Product

|

Applications

The important benefits of high structural strength, good dimensional stability, durability, smooth & glossy surface enable the hardboard ideal use in furniture, door manufacturing, packaging, automative industry.

Example

Hardboard Surface

|

|

| Top: Smooth Gloss Surface | Bottom: Textured Surface |

Storage & Handling

|

Store under shade, dry and leveling area on timber bases. |

|

Handle vertically from both edges with two or more persons to prevent sagging of the board |

Disclaimer

All product images shown are for illustration purposes only. Actual products may varies in term of size, type, brand, version, colour, and other relevant characteristics.

| Size | 3mm |

|---|---|

| 4′ x 8′ (1220mm x 2440mm) |

Yes |